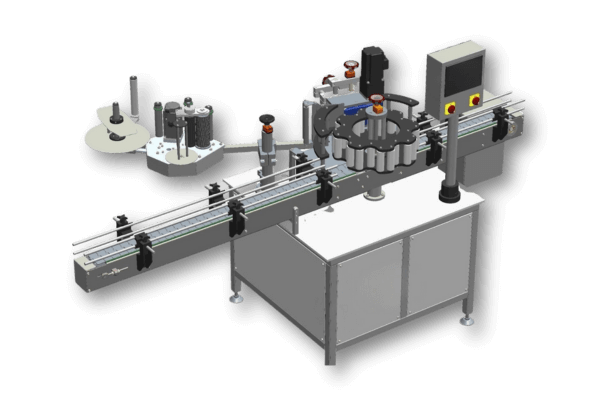

Wrap Around Labeler (Round Bottle)

Home » Wrap Around Labeler (Round Bottle)

Labelling

Wrap Around Labeler (Round Bottle)

Wind Pack Solutions’ Wrap Around Labeler (Round Bottle) is built for manufacturers who demand high precision, speed, and reliability in labeling cylindrical containers—bottles made of plastic, glass, or metal. With a sophisticated servo + PLC system, this machine ensures labels are wrapped evenly around round surfaces, with clean edges, consistent placement, and minimal wastage. It is suitable for full or partial wrap labeling and supports frequent changes in bottles and labels with fast changeovers.

Key Features

Servo PLC based Operation

Accurate label placement

No change parts requirement

Very less down time for change over

One Touch Speed Synchronization

Specification

| Output/Hour* | 3000 to 6000 |

|---|---|

| Direction of Movement | Left to Right |

| Controller | Micro Controller Base HMI |

| PLC | Micro Controller Base HMI |

| HMI | Delta / Mitsubishi Make Touch Screen 3.5inch |

| A.C. Drive | Delta / Mitsubishi Make |

| Servo Motor | 750 Watt Panasonic with Driver- 1 No. |

| Separator Motor | Panasonic / RotoQ / Bonfiglioli / Hindustan |

| Conveyor Motor | 0.5HP Bonfiglioli / Hindustan make 1No. |

| Product Sensor | Leuze / Sick / Panasonic |

| Label Gap Sensor | Leuze / Sick / Panasonic |

|---|---|

| Pressing Device Motor | 0.5 HP / 415 V / 50 HZ |

| Servo motor | 750W |

| Label Accuracy | +/- 1 mm |

| Height of Conveyor | 850 mm to 900 mm Adjustable |

| Machine Dimensions** | 1828 mm (L) x 610 mm (W) x 1200 (H) Approx. |

Utility Requirement

| Electrical Supply | 1 Phase + Neutral + Earthing |

|---|---|

| Electrical Load | 1.5 KW |

Label Specifications

| Length** | 30 mm to 250 mm |

|---|---|

| Height** | 16 mm to 100 mm |

| Roll Diameter | Max 300 mm &Core ID 75 mm |

| Space between two label | Min. 3 mm Clock Wise |

| Round Shape Container Size** | Ø 22 mm to Ø 100 mm Respectively Height 40 mm to 240 mm (Height option for other bottle height available) |

Salient Features

- High Production Speeds.

- SS steel structure cladded with stainless steel 304 sheet to meet GMP norms.

- Microprocessor Based operation

- Accurate label placement.

- No change parts requirements.

- Very less down time for change over.

- Suitable for Glass, Plastic, Pet, Tin, Corrugated containers.