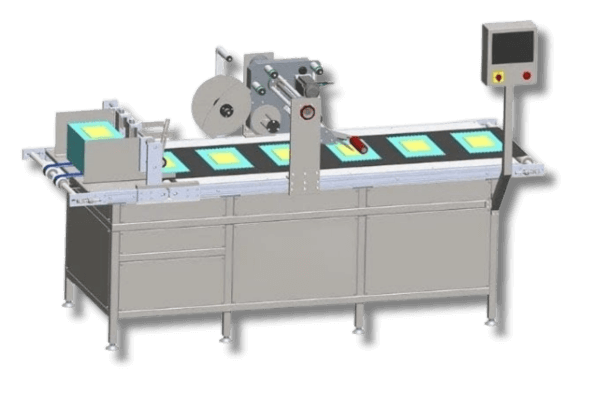

Top Side/Pouch Labeler

Home » Top Side/Pouch Labeler

Labelling

Top Side / Pouch Labeler

The Top Side / Pouch Labeler from Wind Pack Solutions is designed for applications where labels need to be applied to the top surface of containers, lids, trays or pouches — as well as optional side surfaces or full wrap-around if needed. Its compact, high-speed design is especially suited for modern packaging lines in sectors like food, beverages, cosmetics, pharmaceuticals and household chemicals. With minimal change-parts, self-adhesive label compatibility, and robust stainless steel construction, this machine delivers reliability, high throughput and clean presentation.

Key Features

Servo PLC based Operation

Accurate label placement

No change parts requirement

Very less down time for change over

One Touch Speed Synchronization

Specification

| Output/Hour* | Up to 60 BPM |

|---|---|

| Direction of Movement | Left to Right |

| Controller | PLC with HMI based control |

| PLC | Mitsubishi / Delta make |

| HMI | 3.5”Screen, Delta / Mitsubishi make |

| A.C. Drive Conveyor | 0.5 HP Mitsubishi / Delta make |

| A.C. Drive for Feeder | 0.25HP, Delta /Mitsubishi No. 2 |

| Feeder Motor Or Worm Motor | Panasonic / RotoQ / Bonfiglioli / Hindustan |

| Conveyor Motor | 0.5 HP / 415 V / 50 HZ, Panasonic / RotoQ / Bonfiglioli / Hindustan |

| A.C. Drive for Top Conveyor Motor | 0.5 HP, 415 V / 50 HZ, Delta / Mitsubishi |

| Pressing Device Motor | 0.25 HP / 415 V / 50 HZ |

| Servo Motor | 400W, Mitsubishi/Sigma make |

| For Flat Container | Bottle movement through Top Drive |

| Product Sensor | Leuze / Sick / Panasonic |

| Label Gap Sensor | Leuze / Sick / Panasonic |

|---|---|

| For Round Container | Bottle movement through Side Drive |

| Label Accuracy | +/- 1 to 2 mm |

| Conveyor Length | 6-8ft |

| Height of Conveyor | 850 mm (+/- 50mm Adjustable) |

| Top Conveyor Height adjustment | Boss makes height adjustment assemble |

| Feeder Adjustment | Boss make height and deep adjustment assemble |

Utility Requirement

| Electrical Supply | 1 Phase + Neutral + Earthing |

|---|---|

| Electrical Load | 2 KW |

Input Specification

| Roll Diameter | Max 300 mm & ID 75 mm |

|---|---|

| Space between Two Label | Min. 3 mm anti clock wise |

Salient Features

- Label release mechanism.

- PLC controlled product sensor to sense the product.

- Break assembly to avoid variation during releasing of roll.

- HMI Touch Screen to operate machine easily.

- Feeder or Worm Assemble to hold bottle proper and generate the unique distance between two bottles.

- Wrapping unit for wrap around Labeling.

- Wrapping guide with X & Y direction setting.

- Top Conveyor to hold bottle from top and bottom.

- 6-8 Ft. Conveyor to convey the product.

- PLC controlled label gap sensor to sense the gap between two labels.

- PLC base electronic control system for total operation of the machine with programmable L.C.D display (P.L.C.) with programming facility

- Specially designed drive mechanism.

- Dispensing unit to dispense labels.

- Reel mechanism (Size: 305 mm) to hang the roll.

- Machine made from S.S. 304

- A.C. frequency variable drive for variable speed with constant torque