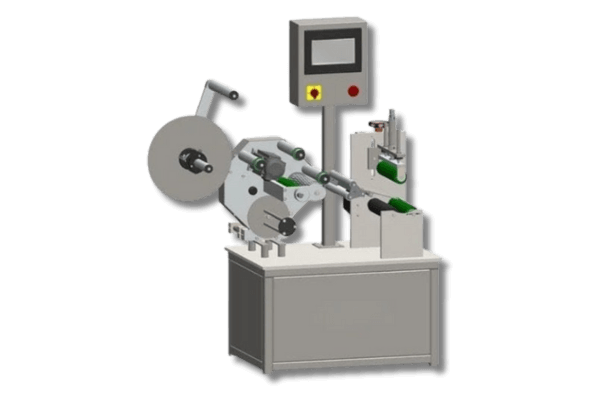

Semi-Automatic Table Top Labeler

Home » Semi-Automatic Table Top Labeler

Labelling

Semi-Automatic Table Top Labeler

The Semi-Automatic Table Top Labeler from Wind Pack Solutions is designed to meet the labeling needs of small to medium-scale production lines. Its compact design ensures it fits seamlessly into limited spaces, making it ideal for startups, laboratories, and businesses with moderate labeling requirements. This machine combines precision, ease of use, and versatility, providing an efficient solution for various labeling applications.

Key Features

High speed 100/200/300

Servo PLC based Operation

Accurate label placement

No change parts requirement

Very less down time for change over

One Touch Speed Synchronization

Specification

| Dispenser Motor (400 Watt Servo) | Panasonic/ Mitsubishi |

|---|---|

| PLC | Delta / Mitsubishi |

| HMI | Delta / Mitsubishi |

| Product Signal | By foot switch |

| Label Gap Sensor | Leuze |

| Speed (Upto 15) | Depends on the product / Label Size & Operator Skill |

| Electricals | 230 V , AC / 50 Hz |

| Pneumatics | Festo / Janatics / SMC |

| Roller Motor (60 Watts) | Panasonics /RotoQ |

|---|---|

| Roller Motor Variable Drive (0.5 HP) | Delta / Mitsubishi |

The Machine Contains

- PLC base electronic control system for total operation of the machine with programmable L.C.D display (P.L.C.) with programming facility

- Dispensing unit to dispense labels

- Reel mechanism (Size: 305 mm) to hang the roll

- Machine made from SS 304

- Label release mechanism

- PLC controlled product Signal by way of Foot Switch to sense the product

- Break assembly to avoid variation during releasing of roll

- PLC controlled label gap sensor to sense the gap between two labels