High Speed Ampoule & Vial Labelling Machine

Home » High Speed Ampoule & Vial Labelling Machine

Labelling

High Speed Ampoule & Vial Labelling Machine

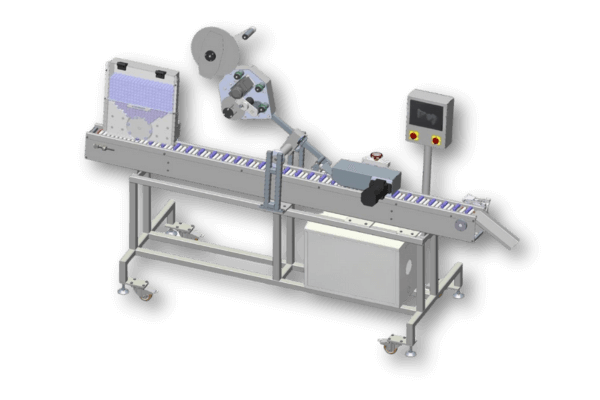

For pharmaceutical, biotech, and related industries, reliability and speed are key. Our High Speed Ampoule & Vial Labelling Machine is built to handle rapid production demands while maintaining flawless label application. Designed with advanced servo & PLC controls, it supports wrap-around, overlap, partial or full sticker labels on small diameter containers like ampoules and vials. With outputs up to 300-400 units per minute (or higher depending on model and label size), it balances speed, precision, and hygiene.

Built to GMP standards, this machine features a vertical rotary / star-wheel feed, high-quality sensors, stainless steel contact surfaces, and safety interlocks to ensure both safety and performance.

Key Features

High speed 100/200/300

Servo PLC based Operation

Accurate label placement

No change parts requirement

Very less down time for change over

One Touch Speed Synchronization

Specification

| Output/ Minute* | Up to 120 Ampoule/Vials |

|---|---|

| Direction of Movement | Left to Right |

| Electric Specification** (Main Motor) | 0.50 HP / 415 V / 50 HZ |

| Electric Specification** (Servo Motor) | 400/750 Watt Panasonic with Driver- 1 No. |

| PLC | Mitsubishi / Delta make |

| HMI | Delta make Touch Screen 3.5 inch |

| A.C. Drive | Delta / Mitsubishi make |

| Conveyor Motor | Panasonic / RotoQ / Bonfiglioli / Hindustan |

| Hopper Motor | Bonfiglioli/ Hindustan / RotorQ |

| Product Sensor | Leuze / Sick / Panasonic |

| Label Accuracy | +/- 1 mm |

|---|---|

| Label Gap Sensor | Leuze / Sick / Panasonic |

| Height of Conveyor | 850 mm ± 50 mm Adjustable |

Utility Requirement

| Electrical Supply | 1 Phase + Neutral + Earthing |

|---|---|

| Electrical Load | 1 KW |

| Air Pressure | Not Required |

Salient Features

- Label release mechanism.

- PLC controlled product sensor to sense the product.

- Break assembly to avoid variation during releasing of roll.

- PLC controlled label gap sensor to sense the gap between two labels.

- PLC base electronic control system for total operation of the machine with programmable L.C.D display.

- Dispensing unit to dispense labels.

- Reel mechanism (Size: 305 mm) to hang the roll.

- Machine made from SS 304

- Electronics/Electricals Delta / Panasonics / Leuze / Bonfiglioli / Hindustan.

- 6 ft. Roller Conveyor to convey the product

- Hoper Assemble for automatic product feeding.