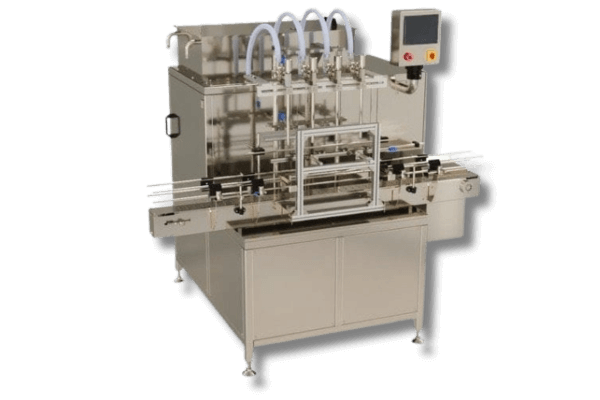

Automatic Multi-Head Servo with Gear Pump Liquid Filling Machine

Home » Automatic Multi-Head Servo with Gear Pump Liquid Filling Machine

Filling

Automatic Multi-Head Servo with Gear Pump Liquid Filling Machine

Wind Pack Solutions’ Automatic Multi-Head Servo with Gear Pump Liquid Filling Machine is designed for companies seeking high throughput, precise dosing, and minimal downtime in liquid product filling lines. Featuring multiple servo-driven gear pumps, this machine offers excellent fill accuracy, versatile fill volume ranges, hygienic stainless steel construction, and smart features like “no bottle-no fill” logic and diving/nozzle motion to reduce foaming.

Whether it’s food, cosmetics, pharmaceuticals, or chemicals, this machine adapts to your requirements with multiple heads (4 / 6 / 8 / 10 etc.), user-friendly PLC & HMI controls, and robust design to meet GMP compliance.

Key Features

No change parts requirement

Very less down time for change over

One Touch Speed Synchronization

Specification

| Number of Head / Syring | 4 Head | 6 Head | 8 Head | 10 Head | 8 Head |

|---|---|---|---|---|---|

| Output/Min* (100ml) | 35 to 40 bpm | 40 to 60 bpm | 60 to 80 bpm | 80 to 100 bpm | 6000 to 12000 BPH |

| Output/Min* (1 Liter) | 18 to 20 bpm | 24 to 30 bpm | 32 to 40 bpm | 40 to 50 bpm | 48 to 60 bpm |

| Output/Min* (5 Liter) | 8 to 10 bpm | 12 to 14 bpm | 16 to 18 bpm | 20 to 24 bpm | 24 to 30 bpm |

| Conveyor Length | 6ft | 8ft | 10-12ft | 12-13ft | 14-16ft |

| PLC | Mitsubishi / Delta make |

|---|---|

| HMI | Mitsubishi / Delta make |

| Servo Motor | 400/750W each motor Mitsubishi make |

| Push Buttons | Telemecanique make |

| Pneumatic Solenoid Valves | Janatics / SMC / Festo makes |

| Pneumatic Cylinders | Janatics / SMC / Festo makes |

| FRL | Janatics / SMC / Festo makes |

| Sensors | Leuze / Sick make |

| Conveyor Height | 850 mm to 900 mm Adjustable |

| Filling Range | 100 ml to 5000 ml |

|---|---|

| Filling System | Servo with Gear Pump |

| Direction of Movement | Left to Right |

| Electric Supply | 415 V/ 50 HZ |

| Conveyor Motor | 0.5 HP / 415 V / 50 HZ Mitsubishi / Bonfiglioli make |

| Conveyor AC Drive | 0.5 HP Mitsubishi / Delta make |

Utility Requirement

| Electrical Supply | 1 Phase + Neutral + Earthing |

|---|---|

| Air Pressure | 6 Bar Pressure 10 CFM |

Input Specification

| Container Neck Diameter** | Minimum 14 mm*** |

|---|---|

| Container Size** | Round Shape (Ø 28 mm to Ø 100 mm) (Height of 58 mm to 240 mm Respectively) Flat / Square (Length of 15 mm to 100 mm) (Width of 10 mm to 50 mm) (Height of 58 mm to 240 mm) |

Salient Features

- No Bottle No Filling System.

- Filling accuracy +/- 1%

- All Contact Parts made of S.S. 316.

- 4 Filling Stations, space saving design.

- Easy to clean.

- Diving Nozzle system to reduce high foaming.

- PLC servo with HMI base controlling system

- Pneumatically controlled nozzles, with No Container No Fill arrangement.

- Drip free nozzle arrangement.

- Drain tray around the machine platform.

- No change part required up to 5000ml.

- Reciprocating filling nozzle with self-centering device.

- Pneumatically operated bottle stopper.

- Safety guard for conveyor gearbox, motor and pneumatic cylinders.

- Safety guard for conveyor gearbox, motor and pneumatic cylinders.