Spot Wrap Labeler

Home » Spot Wrap Labeler

Labelling

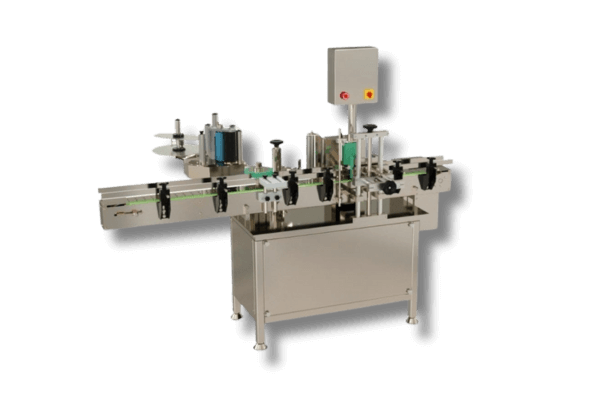

Spot Wrap Labeler Machine Manufacturer

Wind Pack Solutions’ Spot Wrap Labeler is designed for precision label application—ideal for applying spot labels (single labels on a specific face) or partial wrap labels on various container types. Whether your containers are round, flat, or rectangular, this machine offers accurate, clean labelling with minimal setup, making it perfect for cosmetic, food & beverage, pharmaceutical, and FMCG packaging needs.

Built with Servo and PLC controls, a sensor-based mechanism, and high-quality stainless steel construction, the Spot Wrap Labeler assures efficient operation, minimal downtime, and excellent label placement even with varied container shapes/sizes.

Key Features

Servo PLC based Operation

Accurate label placement

No change parts requirement

Very less down time for change over

One Touch Speed Synchronization

Specification

| Output | 15-20 BPM |

|---|---|

| Direction of Movement | Left to Right |

| Controller | PLC based control |

| A.C. Drive Separator | 0.25HP Delta / Mitsubishi |

| PLC | Delta /Mitsubishi make |

| HMI | 3.5” Screen Delta / Mitsubishi make |

| Separator | 60W RotoQ no 1 |

| Product Sensor | Leuze / Sick / Panasonic |

| Label Gap Sensor | Leuze / Sick / Panasonic |

| Power Consumption | Conveyor motor 0.5 HP / 415 V / 50 HZ, Hindustan / Bonfiglioli make |

| Servo motor 400W, Mitsubishi / Panasonic / Sigma make | |

| Wrapping Guide | Roller/Wrapping Belt |

| Label Accuracy | +/- 1 mm |

| Pneumatics | Janatics/SMC |

| Height of Conveyor | 850 mm (+/- 50 mm) Adjustable |

| Length of Conveyor | 6ft long (SS Slat Chain Conveyor) |

Utility Requirement

| Electrical Supply | 1 Phase + Neutral + Earthing |

|---|---|

| Electrical Load | 2 KW |

| Air Supply | 6-8 Bar |

Salient Features

- High Production Speeds.

- Servo PLC Based operation.

- Accurate label placement.

- No change parts requirements.

- Very less down time for change over.

- Suitable for Glass, Plastic, Pet, Tin, Corrugated containers.