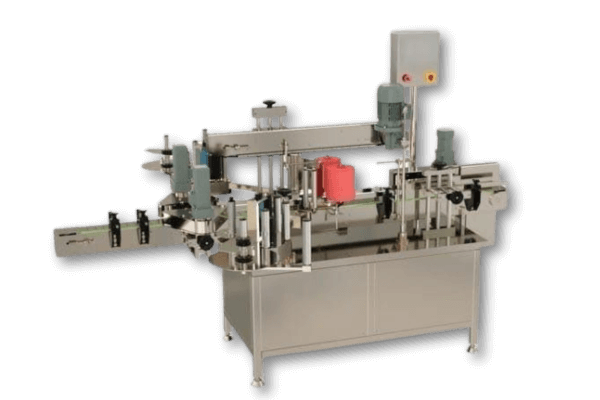

Front & Back Labeler (Round & Flat Bottle)

Home » Front & Back Labeler (Round & Flat Bottle)

Labelling

Front & Back Labeler (Round & Flat Bottle)

In modern packaging lines, applying labels on both the front and back of containers is critical for branding, regulatory information, and aesthetics. Our Front & Back Labeler (Round & Flat Bottle) is designed to apply self-adhesive labels precisely on both faces of round, flat, oval, or square bottles in a single pass. With robust engineering, smart control systems, and hygienic construction, it fits seamlessly into production lines of food & beverage, pharma, cosmetics, and more.

The dual-head labeling system allows simultaneous front and back labeling, reducing process steps and improving throughput.

Key Features

High speed 100/200/300

Servo PLC based Operation

Accurate label placement

No change parts requirement

Very less down time for change over

One Touch Speed Synchronization

Specification

| Output/Hour* | 3600 to 4800 BPH |

|---|---|

| Direction of Movement | Left to Right |

| Controller | PLC with HMI based control |

| PLC | Mitsubishi / Delta make |

| HMI | 3.5”Screen, Delta / Mitsubishi make |

| A.C. Drive Conveyor | 0.5 HP Mitsubishi / Delta make |

| A.C. Drive for Feeder | 0.25HP, Delta /Mitsubishi No. 2 |

| Feeder Motor Or Worm Motor | Panasonic / RotoQ / Bonfiglioli / Hindustan |

| Pressing Device Motor | 0.25 HP / 415 V / 50 HZ |

| Conveyor Motor | 0.5 HP / 415 V / 50 HZ, Panasonic / RotoQ / Bonfiglioli / Hindustan |

| Servo Motor | 750W, Mitsubishi make, 2 Nos. |

| A.C. Drive for Top Conveyor Motor | 0.5 HP, 415 V / 50 HZ, Delta / Mitsubishi |

| For Flat Container | Bottle movement through Top Drive |

| Product Sensor | Leuze / Sick / Panasonic |

| Label Gap Sensor | Leuze / Sick / Panasonic |

|---|---|

| For Round Container | Bottle movement through Side Drive |

| Label Accuracy | +/- 1 to 2 mm |

| Conveyor Length | 8ft |

| Height of Conveyor | 850 mm to 900 mm Adjustable |

| Top Conveyor Height adjustment | Boss makes height adjustment assemble |

| Feeder Adjustment | Boss make height and deep adjustment assemble |

| Machine Dimensions** | 2100 mm (L) x1800 mm (W) x 1500 (H) Approx. |

| Net Weight | 500 Kgs. Approx. |

Utility Requirement

| Electrical Supply | 1 Phase + Neutral + Earthing |

|---|---|

| Electrical Load | 2 KW |

Label Specifications

| Length** | 240mm max |

|---|---|

| Height** | 100 mm max |

| Roll Diameter | Max 300 mm & ID 75 mm |

| Space between two label | Min. 3 mm anti clock wise |

Salient Features

- Label release mechanism.

- PLC controlled product sensor to sense the product.

- Break assembly to avoid variation during releasing of roll.

- HMI Touch Screen to operate machine easily.

- Feeder or Worm Assemble to hold bottle proper and generate the unique distance between two bottles.

- Wrapping unit for wrap around Labeling.

- Wrapping guide with X & Y direction setting.

- Top Conveyor to hold bottle from top and bottom.

- 8 Ft. Conveyor to convey the product.

- PLC base electronic control system for total operation of the machine with programmable L.C.D display (P.L.C.) with programming facility

- Specially designed drive mechanism.

- Dispensing unit to dispense labels.

- Reel mechanism (Size: 305 mm) to hang the roll.

- Machine made from S.S. 304

- A.C. frequency variable drive for variable speed with constant torque