Front & Back Labeler for Flat Bottles

Home » Front & Back Labeler (Flat Bottle)

Labelling

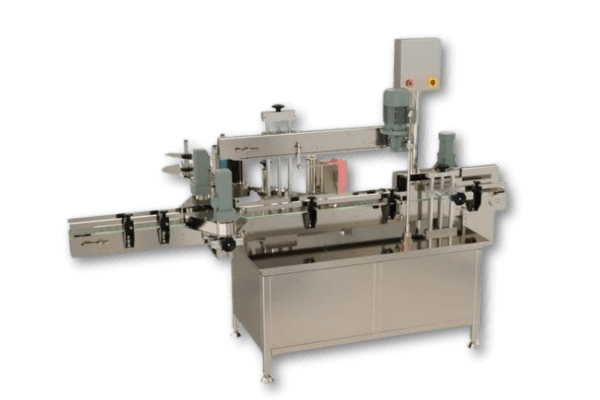

Front & Back Labeler for Flat Bottles

Wind Pack Solutions’ Front & Back Labeler (Flat Bottle) is designed for manufacturers who need precise, high-speed labeling on flat, square, oval, or rectangular bottles or containers. This self-adhesive sticker labeling machine handles both front and back labeling in a single pass, reducing production time and error. With features like PLC control, “no change parts required” design, and top holding belt to stabilize containers, it delivers consistent quality with minimal setup.

Key Features

High speed 100/200/300

Servo PLC based Operation

Accurate label placement

No change parts requirement

Very less down time for change over

One Touch Speed Synchronization

Specification

| Output/Hour* | 6000 to 12000 |

|---|---|

| Direction of Movement | Left to Right |

| Controller | PLC based control |

| PLC | Delta /Mitsubishi make |

| HMI | 3.5”Screen, Delta / Mitsubishi |

| A.C. Drive Conveyor | 0.5HP, Delta / Mitsubishi |

| A.C. Drive for Feeder | 0.25HP, Delta / Mitsubishi |

| Feeder Motor Or Worm Motor | 60W, Panasonic no 2 |

| Product Sensor | Leuze / Sick / Panasonic |

| Conveyor motor | 0.25 HP / 415 V / 50 HZ |

| Pressing device motor | 0.25 HP / 415 V / 50 HZ |

| Servo motor | 750W(each side) |

| Label Gap Sensor | Leuze / Sick / Panasonic |

|---|---|

| Dispenser Motor | 750 Watt , Delta / Mitsubishi |

| Label Accuracy | +/- 1 mm |

| Conveyor Motor | 0.5HP, Panasonic / RotoQ / Bonfiglioli / Hindustan |

| Height of Conveyor | 850 mm to 900 mm Adjustable |

| Top Conveyor Motor | 0.5HP, Panasonic / RotoQ / Bonfiglioli / Hindustan |

| Machine Dimensions** | As Per Layout/referred layout |

Label Specifications

| Length** | 240mm max |

|---|---|

| Height** | 100 mm max |

| Roll Diameter | Max 300 mm & ID 75 mm |

| Space between two label | Min. 3 mm anti clock wise |

Utility Requirement

| Electrical Supply | 1 Phase + Neutral + Earthing |

|---|---|

| Electrical Load | 2 KW |

Salient Features

- High Production Speeds.

- Servo PLC Based operation.

- Accurate label placement.

- No change parts requirements.

- Very less down time for change over.

- Suitable for Glass, Plastic, Pet, Tin, Corrugated containers.