Shrink Sleeve Applicator

Home » Shrink Sleeve Applicator

Wrapper

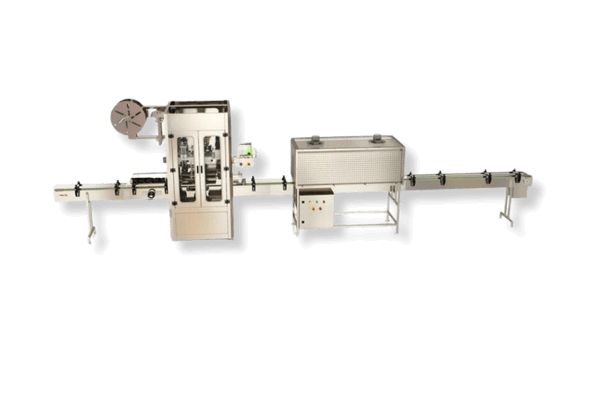

Shrink Sleeve Applicator

Wind Pack Solutions’ Shrink Sleeve Applicator is crafted for businesses aiming for premium label application with full-body or neck/tamper-evident sleeves. Designed with accuracy, efficiency, and hygiene in mind, this single-head automatic applicator integrates smoothly with filling, capping, or sealing lines. Whether for food, beverages, cosmetics, pharmaceuticals or FMCG, it delivers sharp graphics, perfect fit, and consistent performance.

Specification

| PLC | Delta / Mitsubishi |

|---|---|

| HMI / MMI | Delta / Mitsubishi – 7” |

| Servo Motor | Panasonic / Mitsubishi |

| Servo Driver | Panasonic/ Mitsubishi |

| AC Frequency Drive | Delta/ Mitsubishi |

| Sensors | Leuze / Panasonic / Sick / Optex |

| Contactor | Telemecanique / Schneider |

| Relay | Any Well Known Brand |

MATERIAL OF CONSTRUCTION OF SHRINK SLEEVE APPLICATOR:

| Main Body | S.S. 304 |

|---|---|

| Sleeve Mandrill | UHMW / Nylon |

| Feed Worm Mounting Unit | Anodized Aluminum |

| Bottle Carrying Unit | Anodized Aluminum |

| All Shafts | Mild Steel EN 8 Zink Plated |

| Sleeve Pulling Roller | Special Rubber |

| Sleeve Inserting Roller | Special Rubber |

Machine Specification

| Dimension | 2100L X 850 W X 2000 H |

|---|---|

| Weight | 400 Kgs. Approx. |

| Main Input Power Supply | 230 Volts / Single Phase+ Neutral / AC |

| Power Consumption | 1.5 KW |

| Speed | Up to 400 BPM |

| Bottle Diameter Range | 28 mm To 125 mm |

| Bottle Height Range | 50 mm To 280 mm |

| Sleeve Thickness | 0.03 mm To 0.08 mm |

| Sleeve Roll Diameter | 300 mm To 400 mm |

| Sleeve Roll Diameter | 76 mm (3 Inches) |

Salient Features

- ±1% filling accuracy on single dose.

- No Bottle No Filling System.

- Material of Construction for Contact Part will be of SS 316.

- Bottle Conveying by Conveyor. (SS Slat Chain)

- Rigid vibration free construction for trouble free performance.

- S.S. Elegantly matt finished body.

- User friendly and very less maintenance.

- Drip free nozzle.

- Easy to operate PLC with HMI for any kind of filling volume adjustment.

- Each filling head can be operated & monitored through PLC individually.

- Minimum charge overtime, from one size to another container or fill size.

- Nozzle diving and bottle stopping arrangement through Pneumatic System.

- Synchronized two Nos. A.C. drives for main motor & Conveyor Belt.

- Safety Guard for Conveyor Gearbox, Motor and Pneumatic Cylinders.

- Inbuilt protection against over Current, Voltage Fluctuation, Short Circuit in A.C. Frequency Drive.

- The unit is made compact & versatile as per GMP norms.